Aside from actually building the plate, the most crucial part of of this project is the electronics involved. Today I will talk about the contact mics that I will use for this plate reverb.

Now, the contact mics that I will use for this are Piezo pickups from amazon. These are great for my purpose in creating a working plate reverb because they are inexpensive and effective at the same time. However, there is one problem with these. They are unbalanced and do not match well with the inputs from most audio components. This is because the impedances don’t match. This article states that using a typical line input is 50 kilohm. A contact mic like the one I am using needs a much higher impedance, around 1 megaohm.

When the piezo pickup is wired through a typical line input, it creates a high-pass filter of 200 Hz (Green Line), which eliminates the bass. If you wire it into a typical mic input, the impedance is around 7 kilohm and this mismatch causes an even greater high-pass at 1000 Hz (Red Line), which is shown in the graph below:

This would be a problem, but I usually high-pass my reverbs to either 350 or 600 Hz anyways. Those low to mid low frequencies muddy up the sound of a reverb and I end up cutting them anyways. I don’t really see this to be a big problem for me right now with this project. I would love to have that information available, and I found some solutions that I can try in the future.

One of those solutions is to create a FET amplifier which matches the electrical issue involved with piezo mics. There is also a higher quality, lower noise version. These seem easy enough to create, though I don’t know much about them because my knowledge in creating electrical devices is almost null. I will have to do a little research in the future to have the ability to create these for my contact mics.

Another solution is to build a piezo pre-amp created by Alex Rice. He created a phantom powered preamp which the end result is a balanced output for a piezo mic. Zach Poff recreated all of these designs once Alex’s project went off the web. This seems to be a much more doable project for me because all the schematics are there and ready to be put onto a PCB board for production, as seen below.

There is also a great picture showing how to create this same pre-amp on regular perfboard! This is amazing for me because I can just buy this and create a working version very easily, with little electronics knowledge needed.

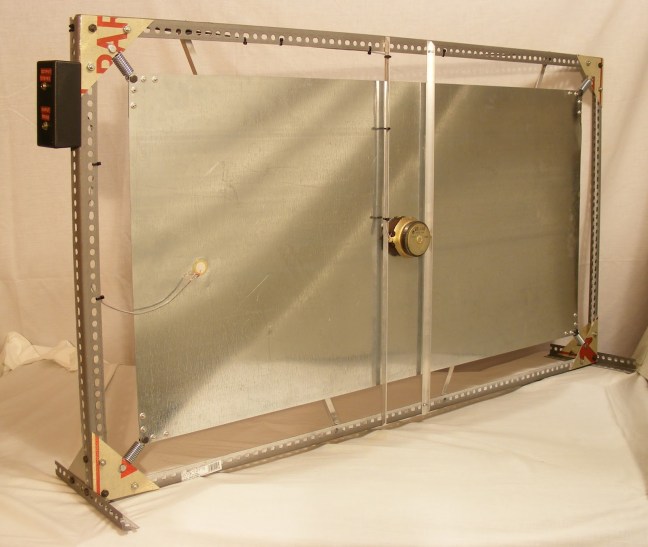

Here is the end result if you follow everything. I think it is a doable improvement after this version of my plate reverb, or if the result of just wiring the mic into a 1/4″ line input doesn’t work out like I want it to, I can try and put it together at the end of my build.

One last solution I found was to take two piezo mics and sandwich them together. Then you would take the “hot” wire from each of them and run them to an XLR’s hot and cold pins. Then you would combine the ground cables from both and run them into the ground of the XLR. This is an interesting way to create a balanced output from the piezo’s but I have one major issue with it. Would it be an omni directional polar pattern because both of the mics are wired into the XLR? Or would it somehow be directional, here is a picture of his end result:

He states that making them directional is a further study and I might contact him to see he if has progressed in it at all. The only way would be to build one and test it, which could possibly be done with this reverb since the piezo mics are fairly cheap. The output on the website sounded pretty well, and this would be the easiest solution to the problem of balancing a piezo mic.

I did find at the end of my research a very easy way to make a contact mic useable with an XLR output, which I will end up trying also in my plate reverb!